We use our extensive equipment both in research projects and on behalf of our customers. In addition to commercially available machines and systems, we have numerous in-house developments and enhancements for special applications.

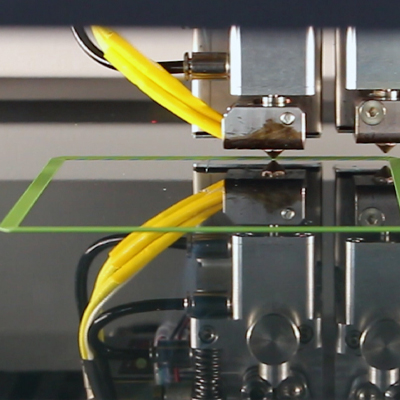

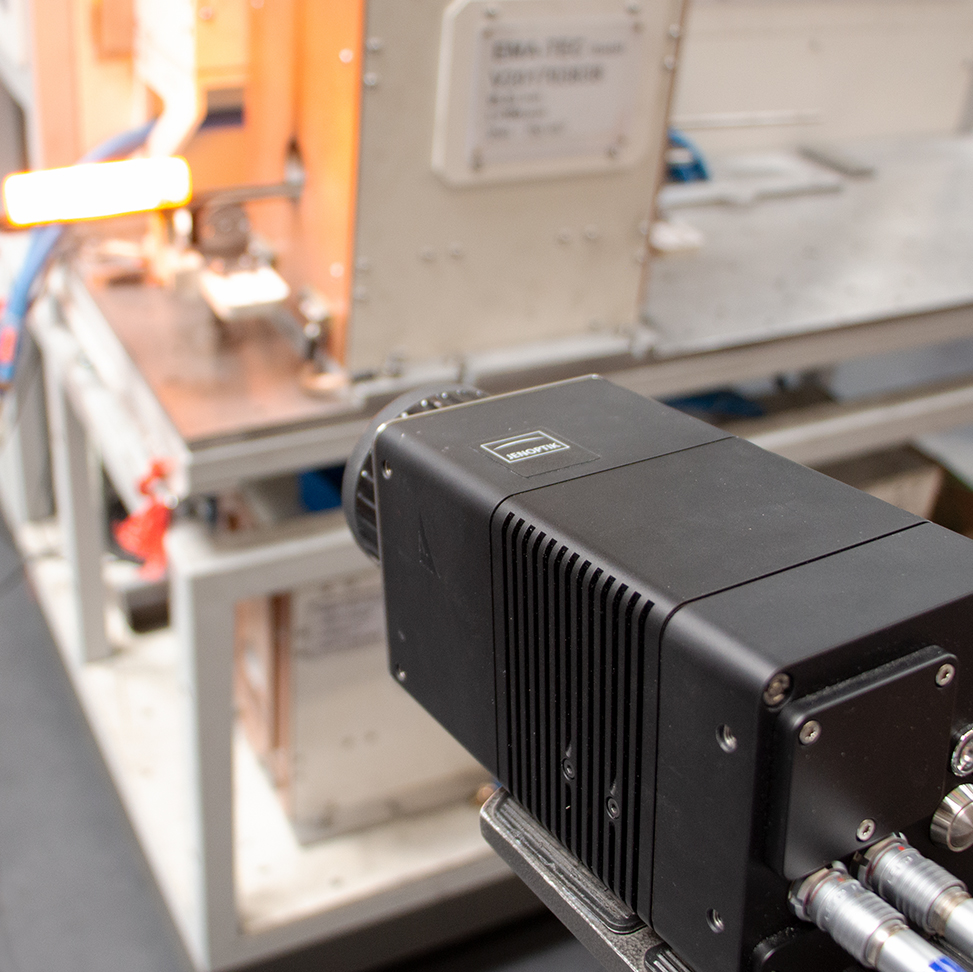

We use AR glasses, 3D printers, testing technology and optical measurement technology for various applications, an induction heating system, special software - including material flow simulations, FEM simulations and ergonomics evaluation -, a laser cutter for prototype construction and much more.

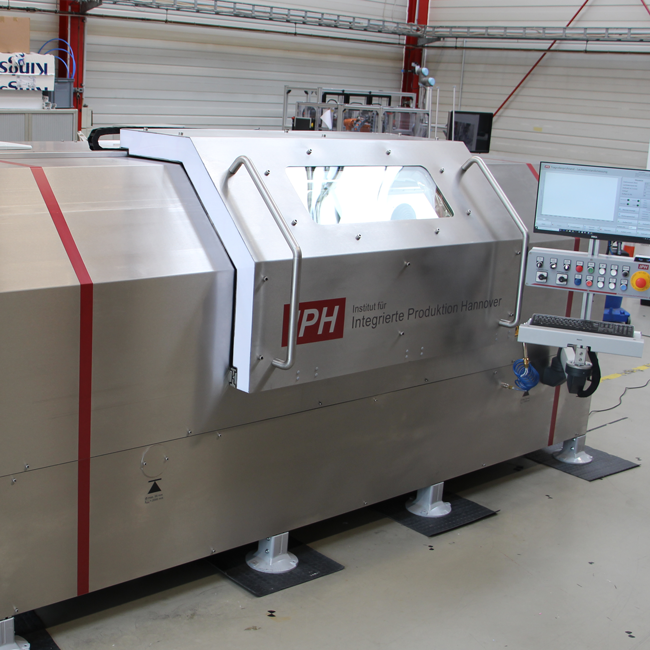

In-house developments include our research drone for indoor flight, our idler roller test bench and our crowss wedge rolling machine.

Our employees benefit from a modern working environment with a creative room, parent-child office, cargo bike and a green break area