At IPH we offer conceptual design and development of assemblies and machine prototypes. According to the individual requirements of our customers and project partners, we first develop different solution concepts. In addition to the functional analysis of the developed concepts, we also perform an economic analysis of the developed solution concepts. Together with the customer, we select a concept that meets both the economic and the technical requirements.

Extensive experience in CAD design and simulations of different manufacturing processes enable us to implement solution concepts for your assemblies and machines, to design them and to manufacture them as prototypes at IPH. At IPH we can carry out the following work, depending on the customer's requirements for the designs:

Together with you, we identify the goals for your design, record your requirements for the components and assemblies to be designed and use these to create a specification sheet.

Based on the specifications, we derive solution concepts for your design, evaluate them e.g. with regard to their functionality and cost-effectiveness, and create initial preliminary designs for the components.

After selecting a suitable solution concept and design, we create the 3D designs using CAD programs for all components and derive technical drawings for them.

Based on the 3D designs, we perform FEM analyses of individual components and assemblies as well as overall designs to verify their structural strength.

Using additive rapid prototyping, we are able to produce models of your designs at short notice and test them for functionality. In addition, we select the most suitable manufacturing processes for the components of your design.

As part of the manufacturer selection process, we identify and evaluate potential suppliers. This includes requesting price information for your components or conducting supplier presentation workshops.

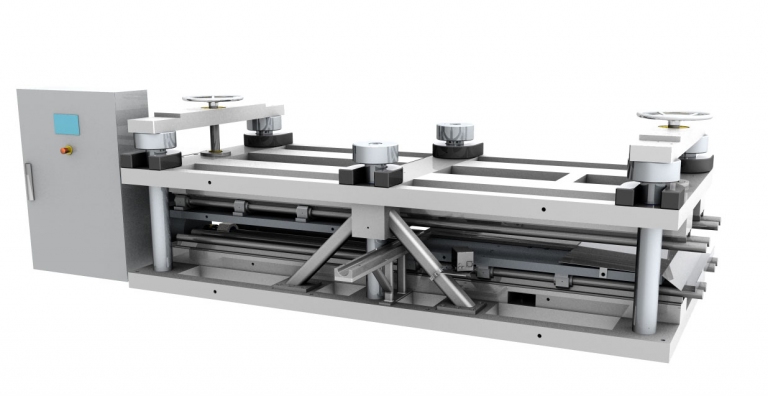

Figure 1: Cross wedge rolling machine developed at IPH

At IPH we have developed a test rig for idlers which is in operation as part of our service offering. Furthermore, we have developed a test stand for low-effort testing of cross wedge rolling processes as well as a low-cost cross wedge rolling machine especially for SMEs (see Fig. 1), which is in use for preliminary tests at one of our project partners on site. From the conceptual design to the consideration of the machine stiffnesses, the design and the assembly, we handle all steps of the entire development cycle of the machine prototype at our IPH.