Our expertise in established and innovative manufacturing processes, such as casting, machining and especially forming, enables us to provide sound advice on how to optimise your processes. We specialise in resource-efficient forming technologies such as flashless forging and cross-wedge rolling.

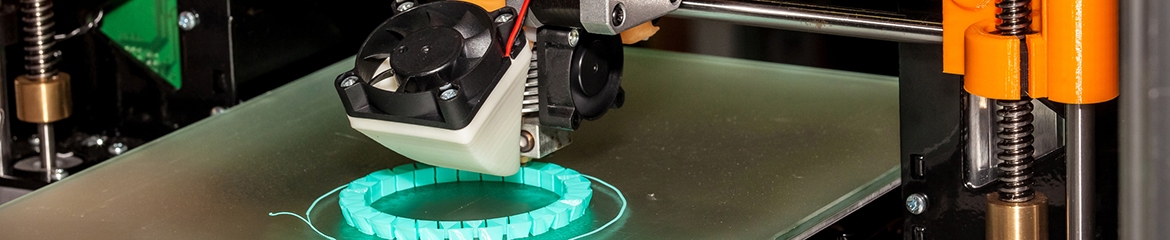

Our areas of expertise include the assessment, selection and roll-out of alternative manufacturing methods, including additive manufacturing. We provide comprehensive potential analyses and technical feasibility studies, and optimise existing processes.

With over 20 years of experience, we also offer forming tests and FEM simulations in addition to process design. Our range of services covers both theoretical principles and practical applications.

Our service modules

The service modules listed below represent complete work units in the field of manufacturing processes. For efficient processing, we have a wide range of tried-and-tested tools that can be used systematically to effectively tackle even complex challenges in potential analysis, process analysis, profitability analysis and technology selection for traditional and alternative manufacturing processes.

We also offer corrective FMEAs for analysing faulty processes where the cause of the fault is not obvious. Our expertise also includes the new field of generative manufacturing processes or additive manufacturing - we offer an overview of the entire spectrum of manufacturing technology and provide you with specific advice on its introduction and implementation in your company.

Thanks to our many years of research activity in the field of forming technology, we can also answer more specialised questions in this range of topics in particular and provide you with advice and support.

Together with you, we identify the goals for your production and incorporate your requirements for the component under consideration (e.g. in terms of costs or quality characteristics).

In this phase, we systematically document the current state. This concerns, for example, an existing component, including the manufacturing process or the materials to be used.

Based on our previous knowledge, we investigate alternative manufacturing processes and describe them, for example in terms of their technical properties, in detailed fact sheets.

Together we will evaluate the manufacturing processes in respect to the fulfillment of requirements and assist you in selecting a suitable alternative to the existing technology.

As part of the vendor selection process, we identify and evaluate potential suppliers. This includes requests for pricing information for your component or conducting workshops for supplier presentation.

In this phase, we support you in the economic analysis of alternative production processes, for example taking into account necessary investments and running costs.

Our service packages

Below we show typical offer contents to optimise your production through alternative manufacturing processes. These include researching, evaluating and selecting alternative production processes as well as procuring the relevant technology or contacting the relevant manufacturing companies. We are also happy to put together customised service packages according to your requirements, including in the field of additive manufacturing and forming technology.

Your current manufacturing process cannot (or can no longer) fulfil your quality or cost requirements? Are you specifically looking for alternative ways to manufacture your components?

Do you not have time for extensive research in your day-to-day work? Then we will be happy to support you in researching, evaluating and selecting potential manufacturing processes

Are you looking specifically for alternative ways to customize your components? You would like to know more about the potential of alternative manufacturing processes? Are you wondering whether other manufacturing processes are cheaper than the technology you are currently using? You lack the time for the systematic selection of a manufacturing process based on technical and economic criteria? Then we would be happy to support you in researching, evaluating and selecting manufacturing processes.

Would you like to digitise and automate the design process for your forming processes? Would you like to shorten the time-consuming and iterative development process for the design of multi-stage sequences and make it more efficient? Then we would be happy to provide you with comprehensive support in the development and programming of customised methods for the automated generation of multi-stage sequences for components manufactured using forming technology.

We can also help you if you want to produce a component by forming. Various forming machines are available at IPH for the experimental testing of forming processes.

IPH offers the evaluation, analysis and selection of manufacturing processes. According to DIN 8580, classic manufacturing processes as a central part of production technology are divided into primary forming processes, forming processes, separation processes (including machining), coating processes, joining processes and processes for changing material properties. There are also new generative manufacturing processes that are used in the field of additive manufacturing, such as 3D printing. For more information on manufacturing technology and manufacturing processes, please click here.

IPH focuses in particular on providing advice on alternative manufacturing processes and on optimising existing manufacturing processes. Cost-effectiveness analysis, potential analysis, process analysis, process optimisation and process selection of manufacturing processes are part of IPH's range of services in the field of alternative manufacturing. Instruments such as process cost analyses and computer simulations are used. With our systematic approach, we offer you sound support in the selection, introduction, implementation and optimisation of manufacturing processes. In addition to creating calculation models for calculating unit costs depending on the batch size, we also carry out supplier research in our consulting projects, including requests for quotations and evaluations.