| Project title | Self-learning multi-stage quality monitoring procedures for (laser) material processing (SmQL) |

|---|---|

| Project duration | 01.12.2018 – 30.11.2021 |

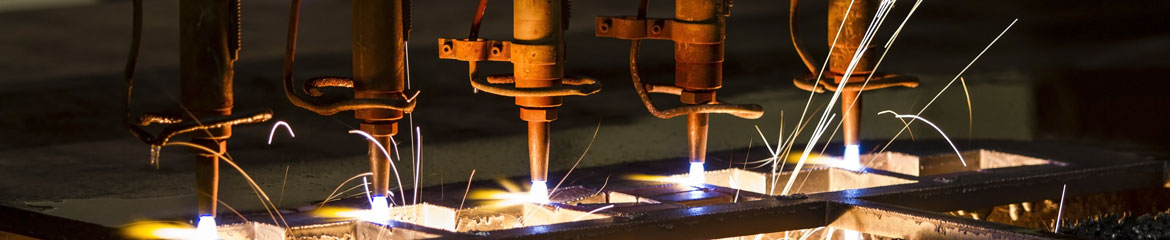

Small and medium-sized companies that supply products in a coordinated process chain (such as the cutting of semi-finished products, followed by laser welding) are confronted with changing tasks and mostly small batch sizes. Due to the increasing product complexity and the increased variety of variants, the effort for the development of production processes in small and medium-sized companies is constantly increasing. The digitalization of process knowledge represents a special challenge for processing small and medium-sized companies in many cases.

Therefore, an expert system is being developed in the "SmQL" research project to support manufacturing companies in the field of laser material processing, process control and process prediction of new products and product variants.

- Sorry, no events available.

Vergangene Termine gefunden

- 05.03.2019, 10:30 h - 16:00 h

- IPH Hannover gGmbH | Hollerithallee 6 | 30419 Hannover

- https://iphhannover-my.sharepoint.com/:b:/g/personal/poschke_iph-hannover_de/Edz-I1abl3hKm78-LbYlLe8Ble2gdDHXU7kFiulI0nCLSA?e=g3mo0u

- Online meeting via MS Teams

- 29.04.2021, 13:00 h - 15:00 h

- IPH Hannover gGmbH | Hollerithallee 6 | 30419 Hannover

- https://iphhannover-my.sharepoint.com/:b:/g/personal/poschke_iph-hannover_de/ES4K4BmygUxHlfuGFjYUnO0B84CBQCUhCzGJVetwPdsj9A?e=dc84JR

- Online meeting via MS Teams

- 16.11.2021, 09:00 h - 12:00 h

- IPH Hannover gGmbH | Hollerithallee 6 | 30419 Hannover

- https://iphhannover-my.sharepoint.com/

- Online meeting via MS Teams

Publications about the project

Product complexity and variant diversity increase the effort for the development of production processes at SMEs. As part of the IGF research project "Self-learning multi-stage quality monitoring processes for (laser) material processing" (AiF No.: 20419N), an expert system was therefore developed for manufacturing companies in the field of laser material processing. The expert system supports users in process control and quality prediction of new products and product variants .

laser material processing, expert system, machine learning

A product-dependent, individual process development represents a main cost driver in laser material processing. Therefore, the expert system SmQL is being developed in an FQS-funded project, in which process knowledge can be stored in a formalized form and represented in rule form. This is intended to minimize times for setup processes and secure knowledge in the company in the long term.

expert system, industry 4.0, laser materials processing