In the fields of internal transportation and the associated automation and conveyor technology, the IPH has extensive knowledge. We offer independent testing services for manufacturers and users of conveyor belt idlers. The running characteristics of conveyor belt idlers are tested in accordance with testing standards DIN 22112, SAB 1313 and DIN ISO 21940-11. For this purpose we dispose of measurement technology and modern test rigs. This enables us to measure, among other things, running resistance, concentricity deviation, axial relocatability, breakaway mass, balancing quality and tightness against water and dust.

As a result of those examinations you get information about the behavior of idlers during operation as well as an evaluation how properties of idlers influence the energy demand of conveyor belt systems.

Testing services

We provide the determination of:

- size and weight of idlers (DIN 22112)

- running resistance (DIN 22112)

- concentricity deviation (DIN 22112)

- axial relocatability (DIN 22112)

- breakaway mass (SAB 1313)

- balancing quality (DIN ISO 1940)

- tightness against water and dust (DIN 22112-3)

We also offer testing services outside the DIN specifications, according to customer requirements.

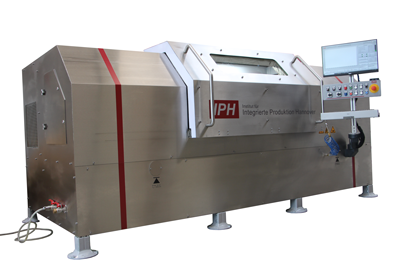

Test rig with climatic chamber

A modern test rig with climate chamber is available for carrying out idler tests. In this climatic chamber, the temperature can be set to values from -40 °C to 60 °C, and relative humidity of up to 100 % is also possible. In this way, a wide range of environmental conditions can be simulated in order to test the behavior of idlers under near-operational conditions.

The technical data of the test rig for a running resistance measurement are listed below:

- Idlers with dimensions according to DIN 15207 and DIN 22112

- Maximum diameter of idler: 250 mm

- Maximum length of axis: 1500 mm

- Maximum load: 3 kN

- Maximum test velocity: 5 m/s

- Ambient temperature: -40 °C to 60 °C

- Relative humidity up to 100 %

Testing of driven idlers

The test rig at IPH can also be used to test driven idlers that have their own electric motor. In this way, IPH can support manufacturers and research institutions in the development of driven idlers.

On the test rig, the driven idler is operated at a defined speed. The drive wheel of the test rig is pressed against the driven idler with a defined force and brakes it with a counter-torque. The influencing factors of load, speed and counter-torque can be varied. Of particular interest is the start-up behavior of the driven idlers under various conditions.

Further tests of conveyor belt components

Based on close cooperation with our partner institute at the Leibniz Universität Hannover, the Institute of Transport and Automation Technology (ITA), further testing services for conveyor components can be offered on request.

-

Overview of other testing services at ITA (in German language)